MODULAR

HOME - TO - GO modular homes for the third Millennia

INTRODUCTION

Prefabrication has been used for Millennia. The oldest engineered roadway, famous Sweet Track, has been built in England in the 3800 BC using ‘prefabricated’ oak planks.

Prefabricated houses were first produced in the United States during the Gold Rush in order to enable quick and effective construction. Prefabrication was later explored by some of the greatest twentieth-century architects as Le Corbusier, Walter Gropius, Marcel Breuer and Frank Lloyd Wright who saw the technique as a natural solution to the problem of housing in modern society.

ONGOING PROBLEMS

1.0 STIGMA

Despite obvious advantages, prefabricated building always had a stigma of being cheap, tacky and poorly designed, with no character. This, for sure, has to change, and quickly.

2.0 MASS PRODUCTION

The number of units had never managed to justify cost for design and development. Cost of time (in millions of hours), spent on a car design will be spread across the entire production run. Prefabricated buildings appeared to be not only tacky, but poorly detailed and not as cost effective as expected.

3.0 LOCATION

The 21st century is witnessing an amazing progress in manufacturing industry and mass communication. Parts of our car or TV are produced at one place, assembled thousands miles away, and sold all around the world. Building industry is not following that progress.

OUR SOLUTION

We believe that all what we learned from manufacturing industry could be implemented in buildings. We believe it is possible to design building at one place, build it elsewhere and put it together anywhere in the world.

GOOD DESIGN

MASS PRODUCTION

LOW COST

1.0 STIGMA

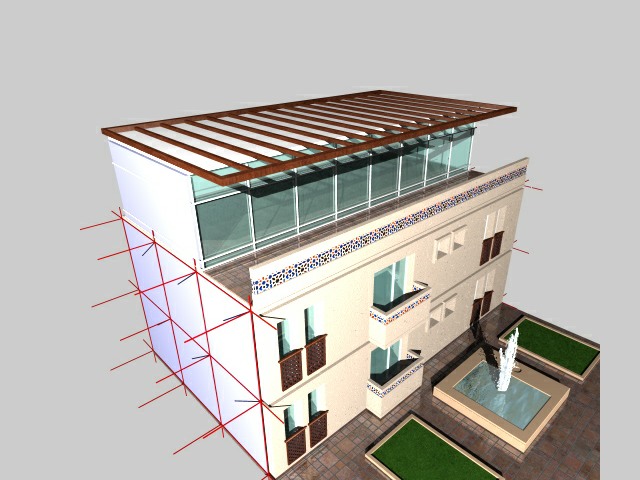

Our design is unique, contemporary, chic. We are proving possible to get prefabricated buildings full of character, and pleasant to live in.

2.0 MASS PRODUCTION

Our aim is not to produce a handful of units, but thousands, in order to justify design cost. Strictly controlled, standardised modular design will minimise number of components, and at the same time maximise layout options.

3.0 LOCATION

All our buildings are designed in UK, steel frames manufactured in India and China, bathrooms and kitchens in Eastern Europe, and assembled in any location in the world, with local regulations fully implemented.

OUR SYSTEM

Simple standardised steel frame structure, properly insulated with fully fitted services, complemented with individually designed exterior panels and landscaping features will create unique developments.

Our standard unit, S- POD, is designed with transport facilities in mind. Overall size is similar to the standard container, easily transported by road, by rail or by the sea.

Modular kitchens and bathrooms are separately developed and fixed to the pods in the assembly plant.

Exterior panels are designed individually. Number of different finishes, materials, colours and styles will be applied in order to give that unique – contemporary, high tech, traditional or regional feeling. It is amazing to see what a difference cladding can impose on final appearance of the building.